The BMW headlight I found is at a strange angle and it needs adjustment. I suspect in a previous life it is been crashed. Now as I have the head in bits this a good time to try and fix a few things. Now I did try and order replacement parts online but a company offering the parts and having them available on their website for ordering turned around and said sorry we don’t have the bits. The left me the option of refit and ignore the headlight that is pointing the wrong way or try and fix it myself.

Headlight removed after a bit of hacksawing and you can see the two bolts, they are meant to rotate, but they don’t. Placing the bolt in the vice and twisting just twisted the bolts. This meant I had to drill them out, I tried the pillar drill but drill bit would wander so I got the hand drill out and did it myself.

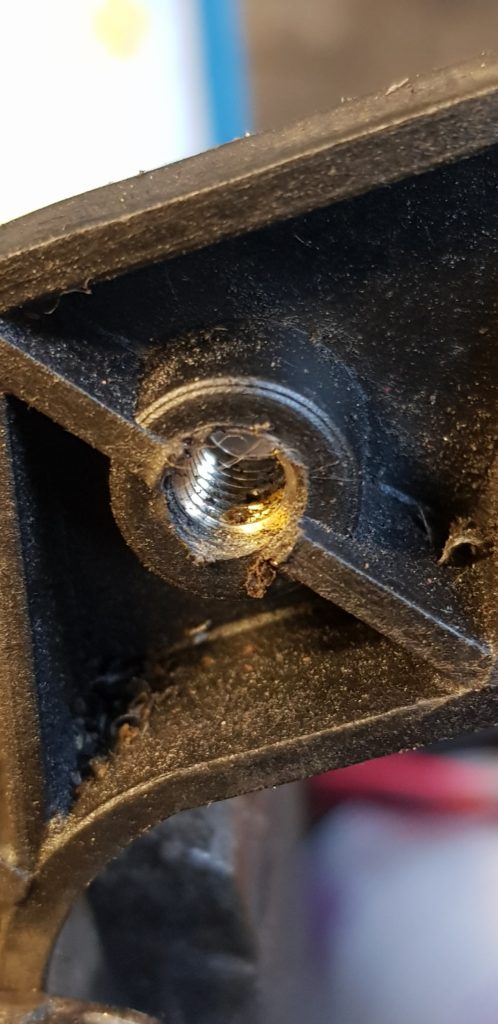

It is not pretty but I meant it could rotate the bolt out. To prevent this happening again I decided that I could use an M5 wire insert (yeah I like them) with a A2 stainless bolt.

Then I turned to the headlight and the plastic cups at that end, it was a pain to get out but good use of pliers and it worked.

Only for me to see the next problem, the bolt heads,

Yup they are rounded, grr. A quick measure suggested about 7mm. This meant I had to take off quite a bit of material from A2 Stainless.

With the aid of the bench grinder, I started to do it by hand, that was too slow so I fitted the bolt to the drill and set to it. The first bolt was nice and easy.

Did the second, and got overexcited,

But I tried another bolt, I had spares. Got it to work fine. Though I suspect I will be in trouble with the proper engineers at my abuse to the stone on the grinder.

With a bit of faffing, I soon refitted the bolts. The BMW used a thumbwheel that sat on two flats ground into the bolt. This often means the thumbwheel falls off. I had purchased some nylon wing nuts as at the time of buying bits I wasn’t sure how the headlight adjustment worked as everything was rusted in place. With the extra know-how after taking it apart, I need to find a way to lock the wing nut in place so I can use it to adjust the light. So a Flange Nut (with serrated edge) and a nylock nut have been used to lock it into place.

Another small task that kept my happy in the shed for a few hours.