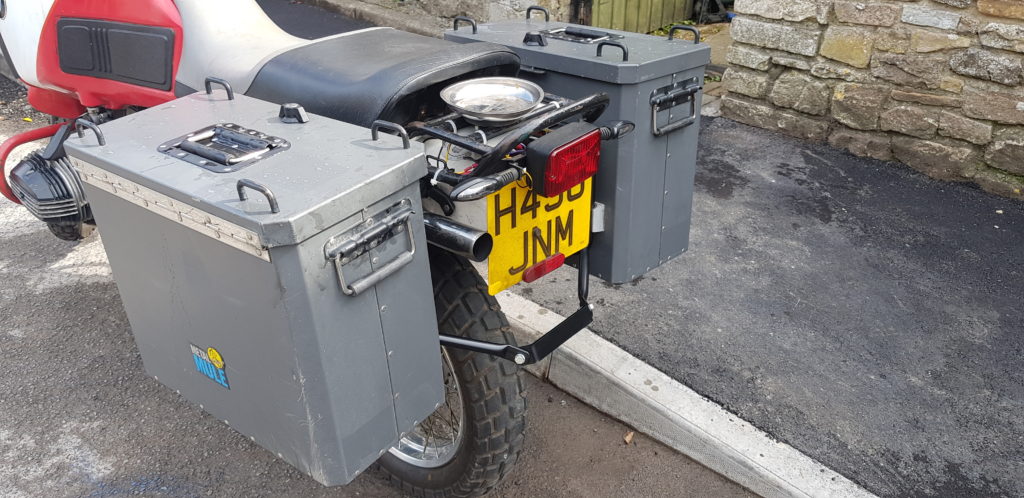

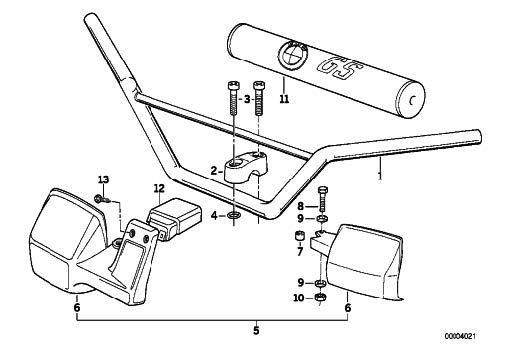

While working on the bike I had noted the rear brake light isn’t standard and just an old Britax one from a trailer. Even worse the bulb holder isn’t properly seated so it rests against the lens and is starting to make a mess of it. I looked into buying an original(ish) one but they aren’t cheap for the whole unit and as the rear mudguard has been cut I doubt it would fit anyway. There is LED kit for it but again that would end up with me spending almost £101.40 for a rear brake light.

So I asked if anyone had tried to make one and I got told it isn’t worth the effort etc. That lead me to think OK, I will just buy a tidy looking cheap one from China to replace the one I have and for £3.50, I did. It arrived and was much smaller than I would have preferred.

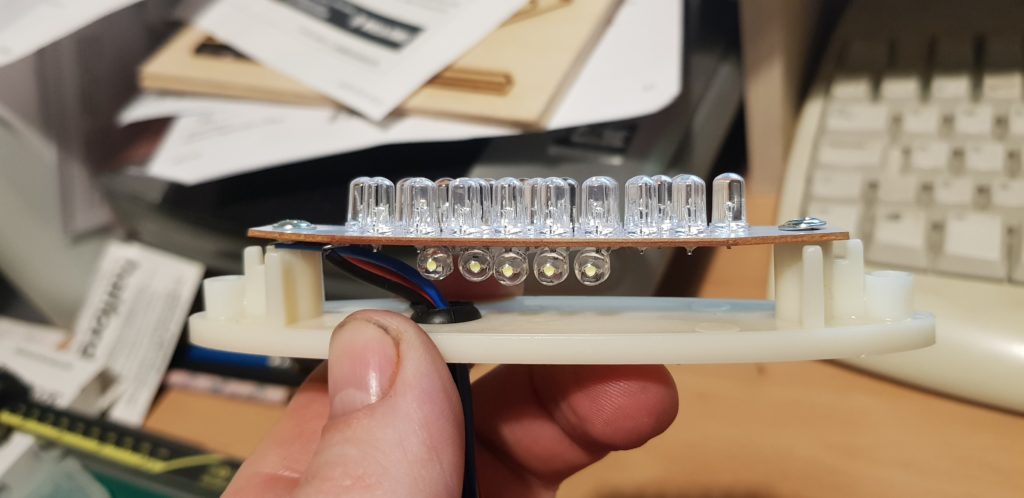

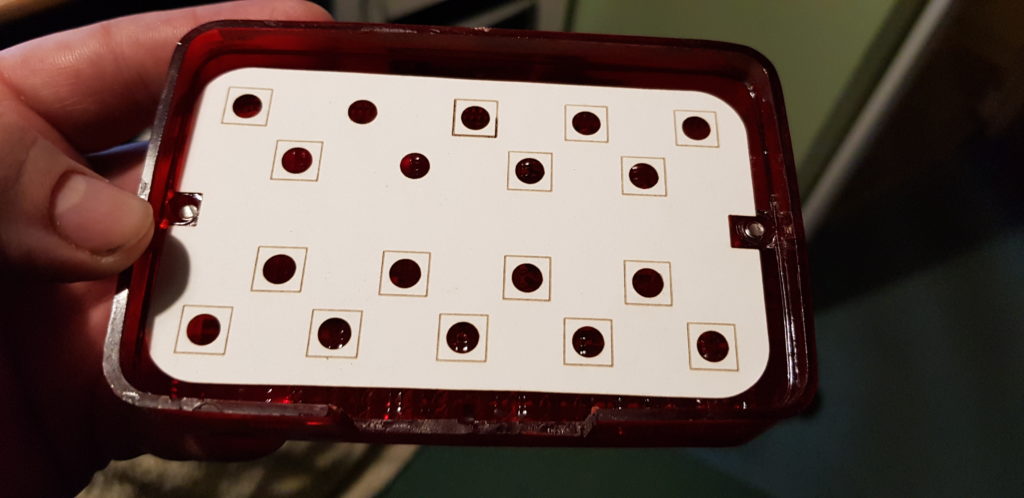

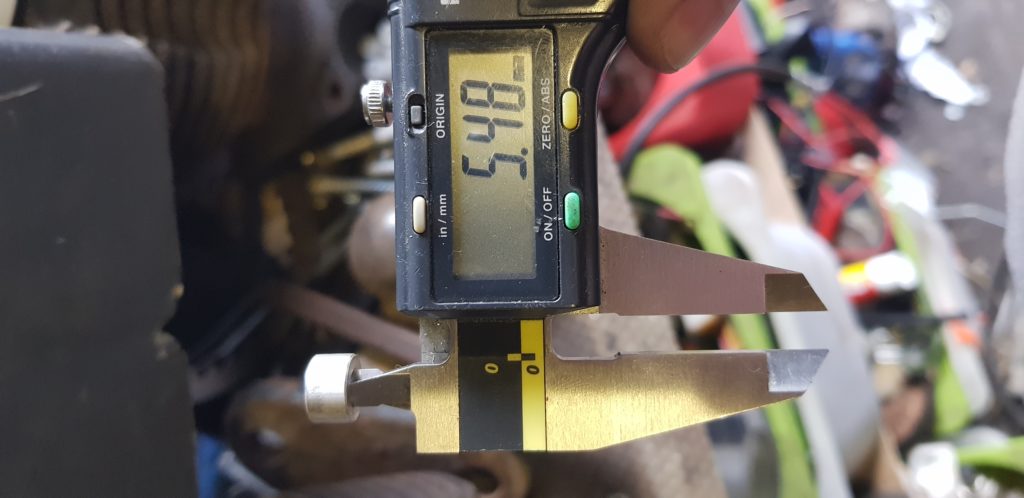

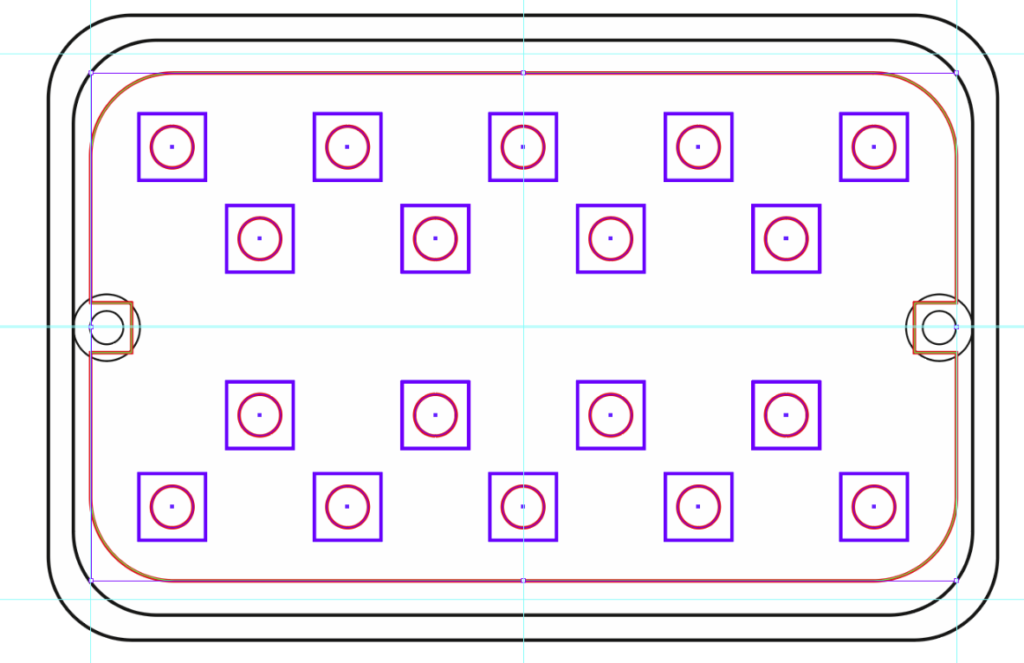

Sod it I thought, let us have a go at making one. I dug out some LEDs I had bought for a project and set to the task of making an insert to hold the LEDs. A bit of measurement here and some Illustrator there I had a fairly good idea of what I was after, I did design it to have even more LEDs but I only had 20 so had to reduce it down a bit.

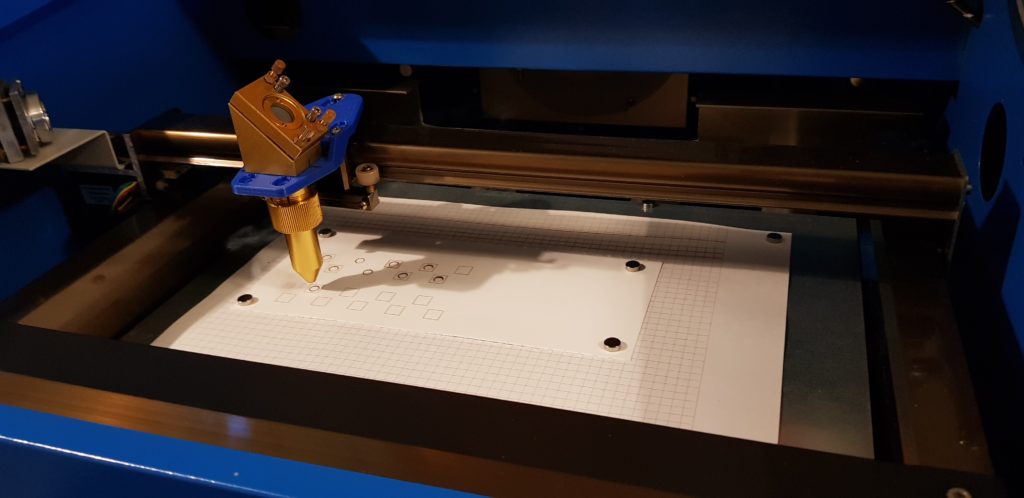

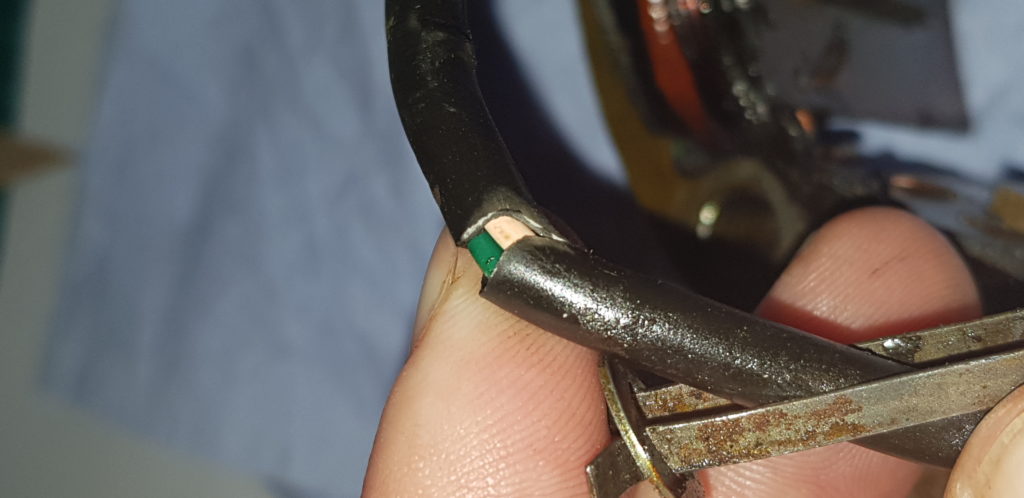

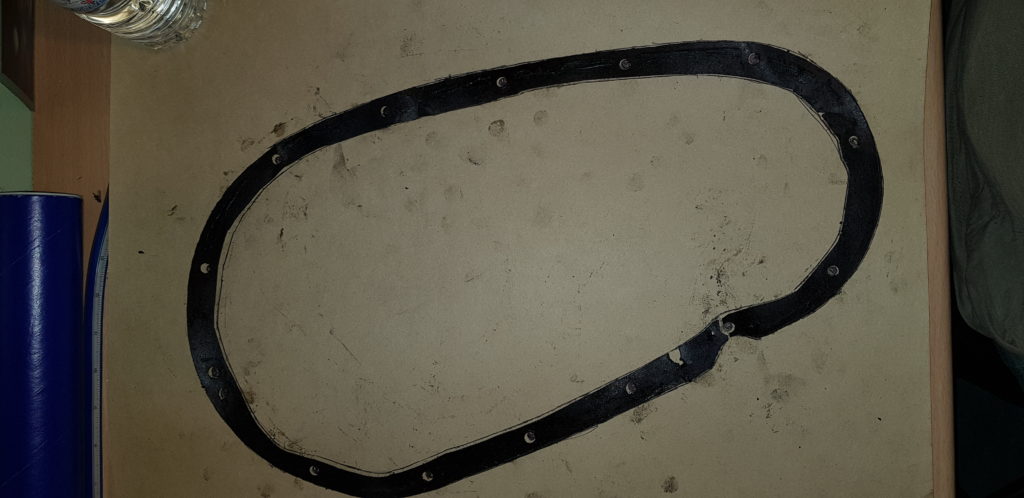

I am able to cheat a little as I have a Chinese 40W laser cutter and some Perspex that can be used. It took 3 runs to cut all the way through but it is a nice neat cut and does the job.

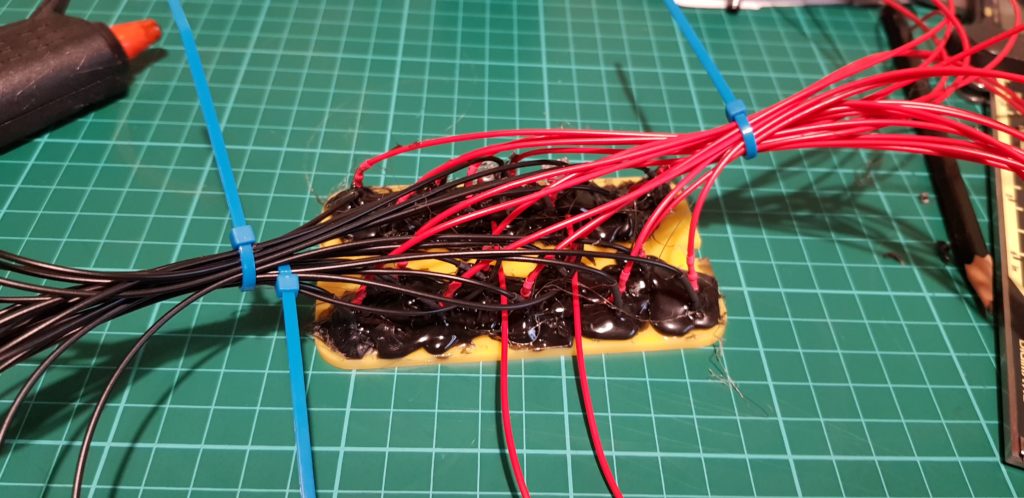

The LEDs aren’t standard shape therefore I used a hotglue gun to stick them in place. Its not neat but this is more a proof of concept.

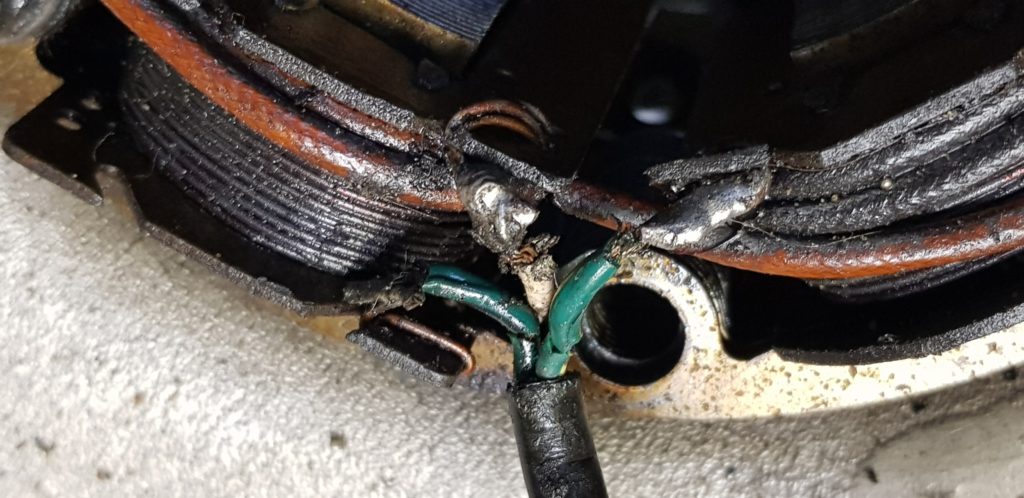

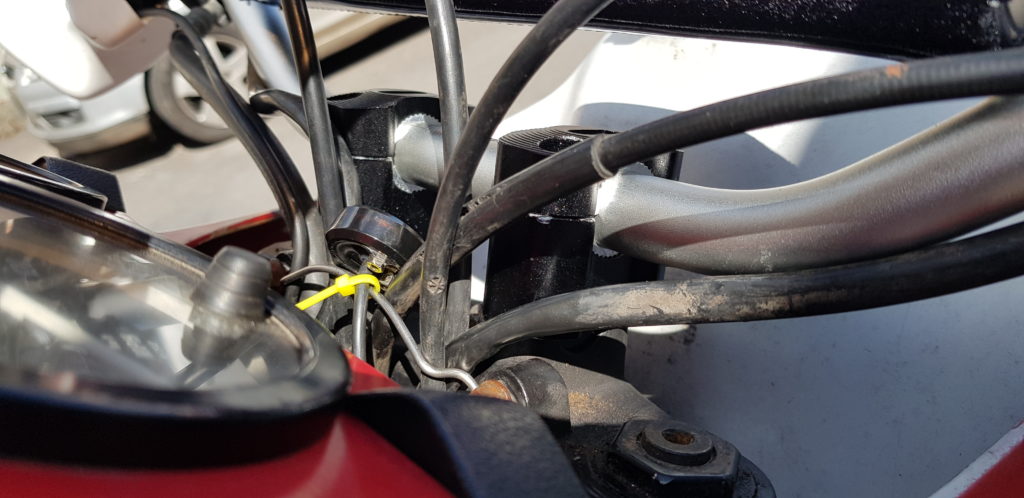

Now time to tidy the wiring up.

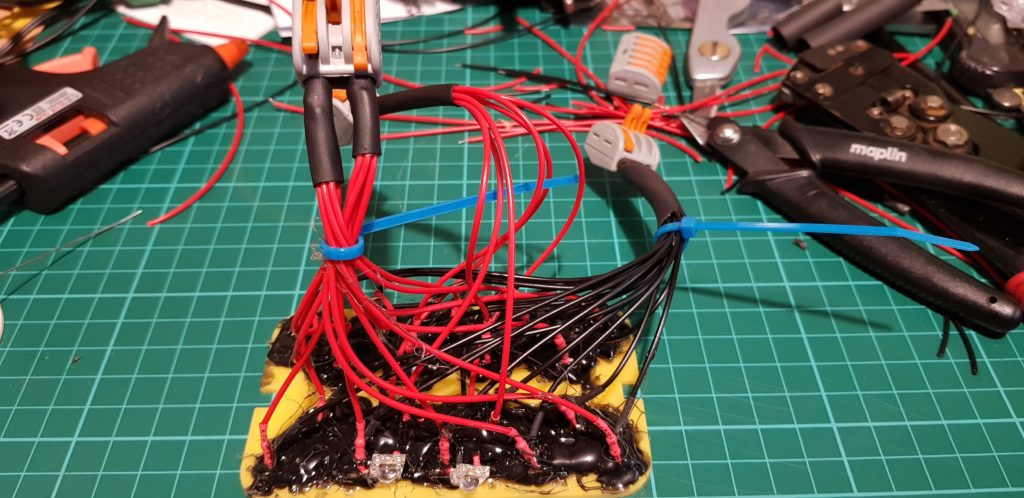

Then add pick which ones I wanted to use for standard tail and brake.

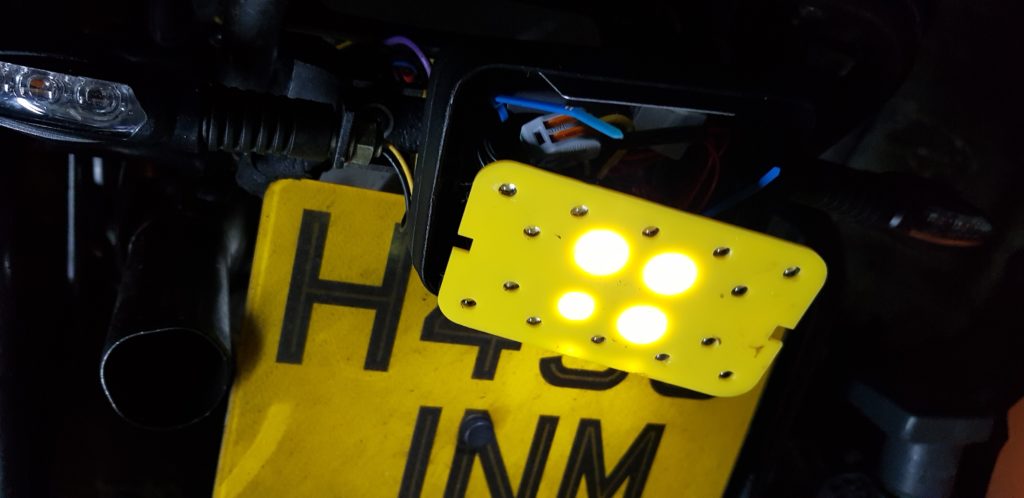

I soldered the wires and then used some Wago connectors to go on the end. They have a nice latching system and it means easy removal if it doesn’t work. They are also rated enough for the task I want.

A quick fit to the bike, and time to test.

Then fitted its even better.

FYI the LEDs I had have all got little resistors so they run fine on 12V. I may have another go with a neater solution later. I could possibly use some of the LED strips you can buy.