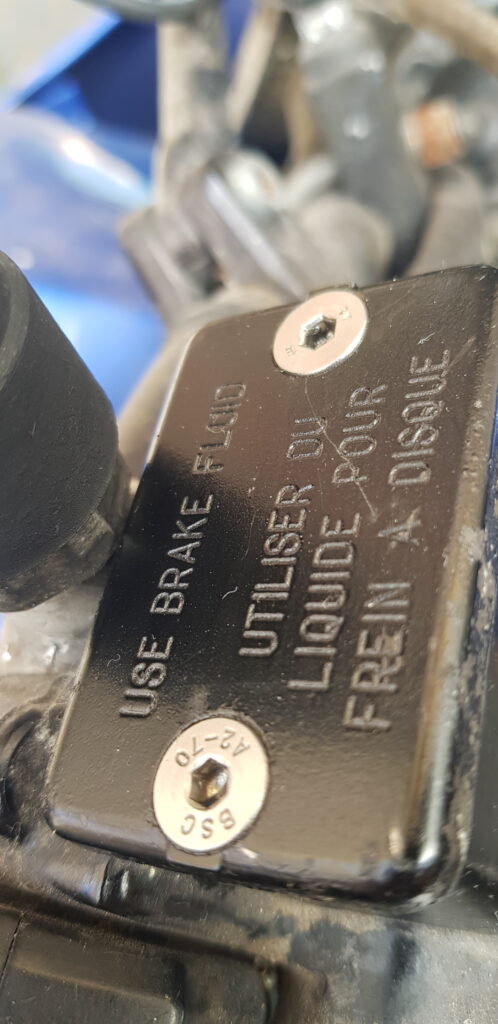

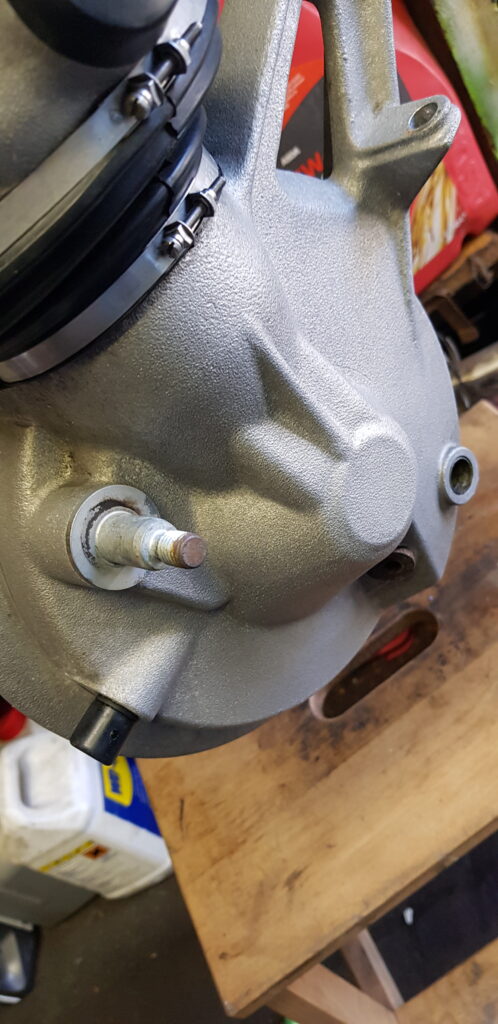

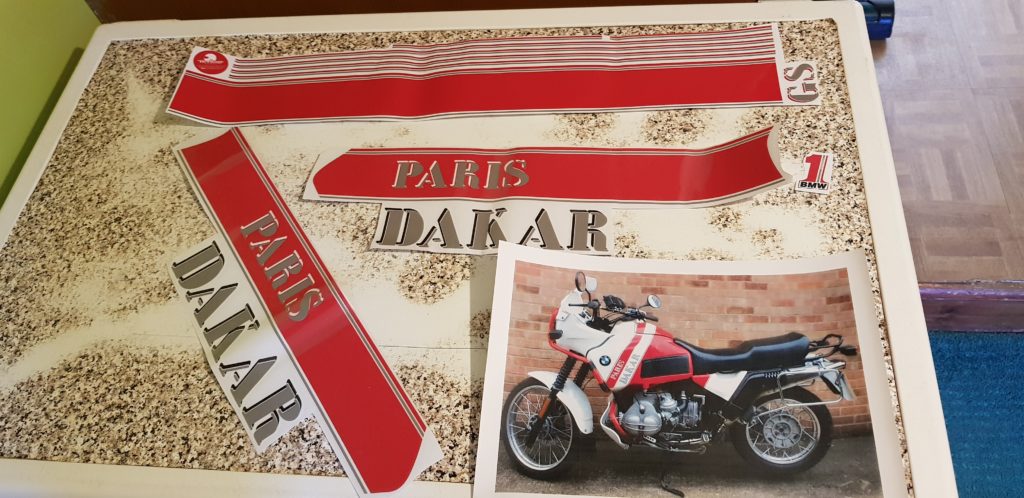

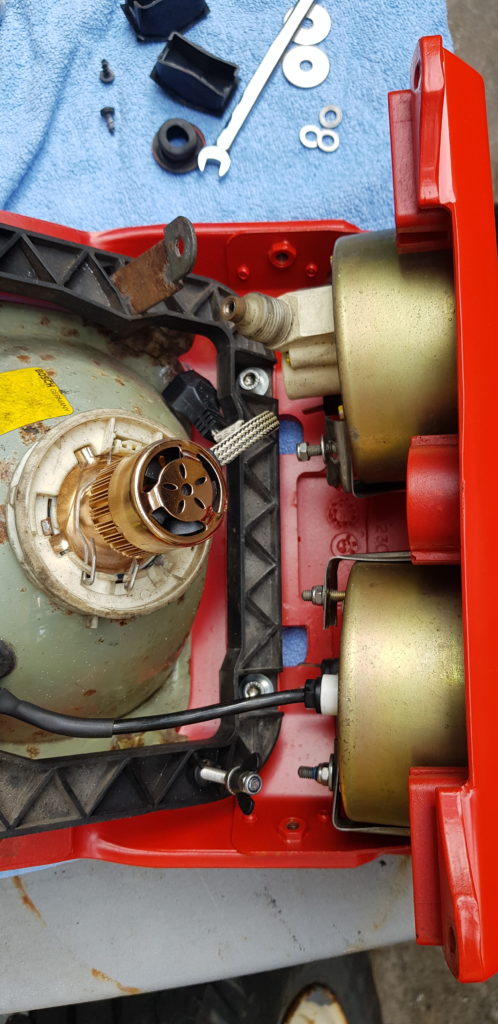

Due to COVID-19 etc I spend 2020 doing some of the tarting up of the bikes. I had planned to get out on the bike but after the extended lockdown I decided to wait for the weather to improve and to get some other stuff sorted out. Then as we got out of the lockdown the weather was rubbish when I wanted to ride but then I did get out. I managed to write up my rides and post them elsewhere but did not update the blog.

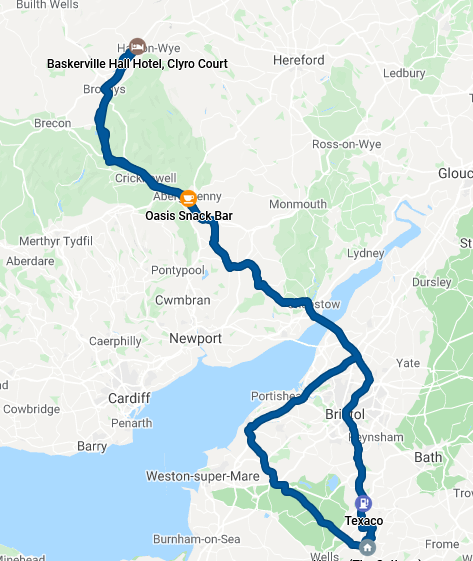

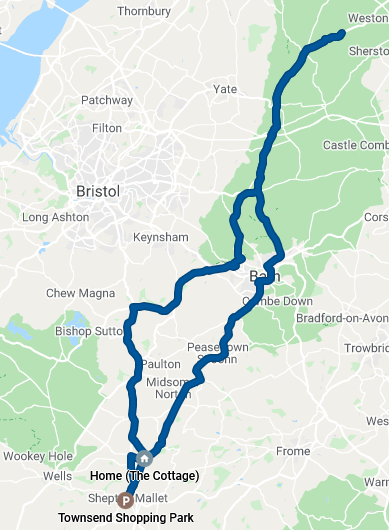

1st of May – A quick ride to Baskerville Hall – 5hrs 200miles

It has been 2 years since I last visited the Baskerville Hall for the annual SoS (Start of Season) so as the BMW had a fresh MOT I was hoping for a day where I feel like going for a longer ride. I have ridden extraordinarily little for the past year or so due to covid and bikes that have had teething problems, so I was a bit wary but in for a penny in for a pound.

I had a nice ride up to Baskerville Hall. Bristol was Bristol and I managed to flex some of my filtering skills even if the BMW does feel a bit of a wide bike and avoided most of the wet weather except for Crickhowell which it tipped down with rain and hail and I got a bit damp and I really felt the cold. I made the mistake of taking the enduro lid with no googles, just some tinted safety glasses. Got to Baskerville Hall and it was empty, but I could hear some bikes up in the woods playing.

It was starting to drizzle so I decided to make my way home via the usual interesting roads. I stopped in Abergavenny for a brew, pee and to stretch my legs.

The cubby box has its uses

Tea at the Oasis Cafe

Having not ridden far for a while it was getting to me a little. Arms and thighs. Ass was OK which was new as the KLR650 seat can become a plank over time. I carried on and decided to avoid Bristol on the way back and took to Clevedon and a short ride up through Burrington. During the last bits, I noted the wind and a chill in the air. I was keen to make it home before the rain, but a couple of loud cars were racing so I had to slow down to avoid being a victim of their sudden overtakes on the cars ahead. Then about 2 miles from home, rain and hail hit hard, I had to back it off as the tyres are old and rubbish and I did not want to ruin a good ride by falling off near home.

So that was 200miles of riding on the R100GS PD done. I can say the bike is awesome even on 16 year old big trail bike tyres (new ones on the way). She has most of the speed and power of my old R1100R but without its desire to kill me when I get nervous. It has the confidence inspiring ability that the KLR650 gives me but with extra smoothness. Though it, not my best riding and I was taking it gentle.

Me, well I am feeling it now. I do miss not being a daily biker as I have aches that I know are due to a lack of bike time.

22nd of May – New Boots – 2hrs 40mins 75miles

Well, they finally arrived, a set of Continental tyres, a TK70 for the front and the TK70 Rocks for the rear. After fitting them I took it for a ride and promptly took the bike onto a local byway I was a bit unnerved by a tendency of them to tramline on the roads.

I did make my way out of a trip a bit further but hit the rain so turned around and came back as it was close to dinner time.

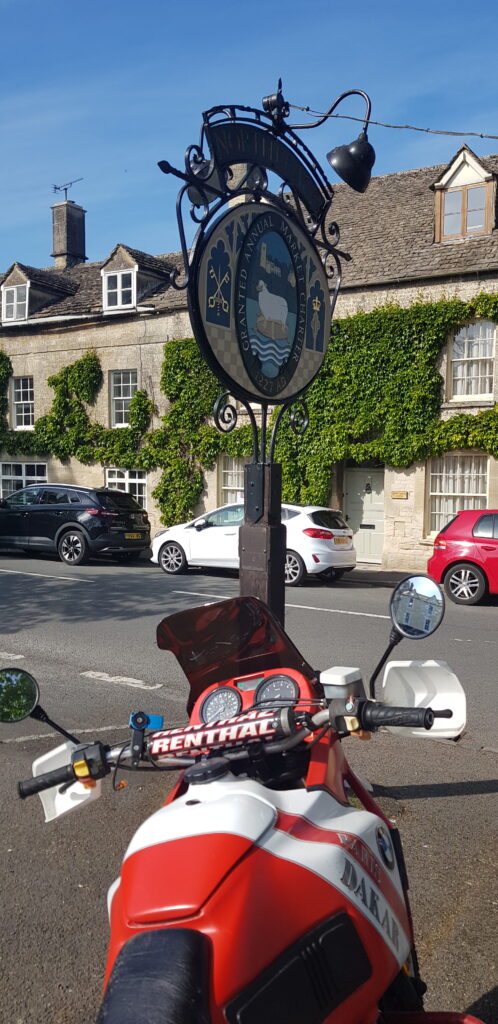

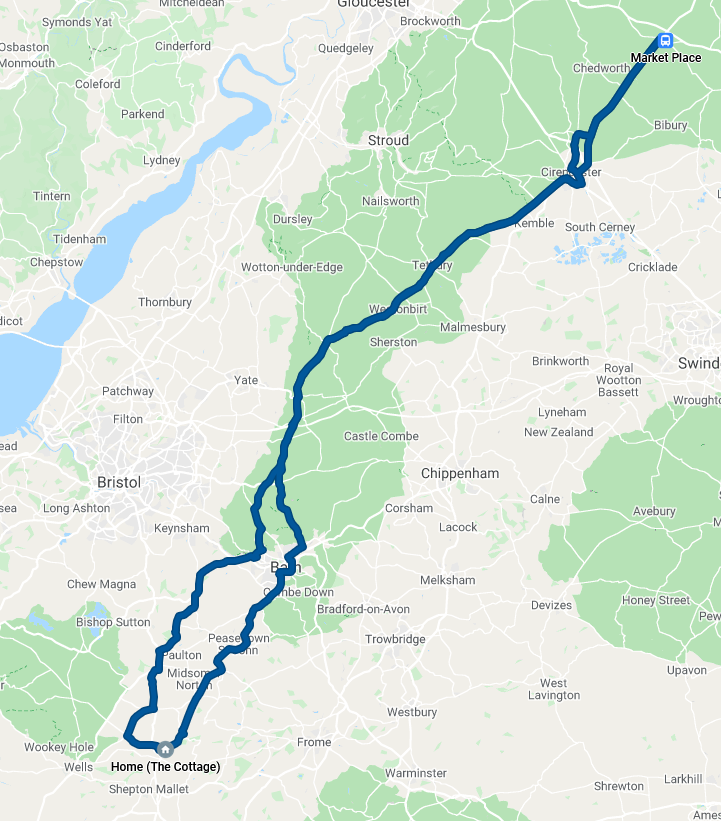

30th of May – A trip to Northleach to find nobody home. 3hrs 30mins 123miles

Ever since I bought the BMW Ian of Ixion has been asking to see the bike and even offered to buy it off me. So as the weather was nice, and I wanted to go for a ride I popped up to his only to find he had gone off for the day with his wife.

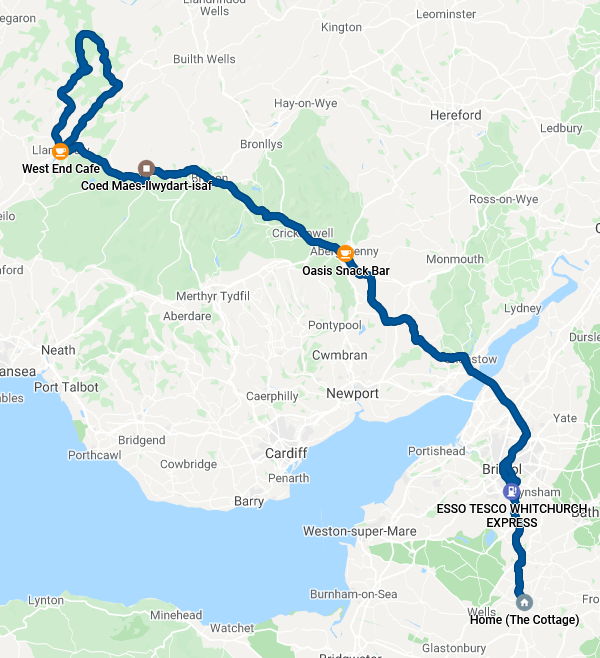

31st of May – Quick ride to Wales and back – 8hrs 273miles

Well after yesterday’s trip to Northleach. I decided to go for a quick ride around Wales. I did invite people from the Internet to meet me at the Cafe, but none turned up. I left home at a sensible 8 am and got to the Oasis Cafe in Abergavenny for about 9:45an via Chepstow, Usk etc. I had a cup of tea and a bacon sarnie then continued towards Brecon where I took to the back roads to avoid the snore that is the A40, whereupon I came across a chap on the modern Ténéré.

The clutch had gone, he mate had gone to M&P to get another and he had made contact with an Overlanding Specialist that lives a few miles up the road, the specialist turns up and suggests that we tow the bike to his workshop, looks at me. I offered to have a go, there was a strap between me and the Ténéré, I started to pull but the anchor point on his bike was off centre and was pulling me, I did ok for 10m but then a snatch and it caught the bars, and my little legs could not save it, so I fell off.

I left him as the other chap did not seem to like my question of “don’t you have a trailer”? so it was suggested I leave. I carried onto Llandovery and stopped for Cake and a drink.

Headed up into the hills and went via the damn/lake, came down “The Devils Staircase” and had a good ride. There was one car driver that was being a bit ignorant and would not let me past, but I got there in the end.

I decided to just keep going to rode back to Llandovery and thought for the sake of it I would see if the chap got towed to the workshop, he and his mate were there trying to figure out what thing they got wrong for it not to work with the new clutch, but they seemed happy enough to I plugged on into Brecon, Abergavenny, Usk, Chepstow and home.

All in all, 273miles and I was back at 6 pm.

I do have to admit I did let two cars overtake me, but they were keeping up with me even when I was making good progress and I think they were having a play to when I got to a straight, I just let them go past, then I am not worried they would drive into the back end of me.

12th of June – Headed South for a change. 6hrs 250miles

Went for another ride, decided to go down the A39 to Porlock and see how far I could get before making the ride home.

I made my way towards Taunton where I managed to find some Fraggle Standard Road (grass growing up the middle of the road, narrow, lots of hedges etc). Joining the A39 at roughly Aisholt, I then trundled down and finally got to Porlock which for those that have not ridden it, it is fun it holds the title of the steepest A-road in the United Kingdom, approaching 1 in 4 (25%) in places. Had a bit of a moment when the car in front slowed, slowed some more I was almost about to overtake it when they got it into gear and then carried on. I do enjoy riding a torque monster of a BMW. I carried on for a while longer, passing some roads that I last rode along with InkyAnn, Flymo and Pauline IIRC. Even past the pub that we stopped at last time for refreshments. As I rode out of Barnstaple, I had to do my one and only U-turn, the roundabout with sign that just said, Landkey or Bishops Tawton, I choose wrong.

I eventually got down to Kilkhampton and by then I was aching a bit and after 3hr 45min and 126 miles since I last stopped, I thought it would be a good idea to see if someone were in, and they were. Finally, on one of my rides outs I managed to find someone at home. So, I stopped to see Ceilia along with Ann and Kevin even saw Arya which I have not seen in quite a few years and to make me feel older she is learning to drive.

After getting a drink and talking bikes for a while. I made my way home via the quicker route (so boring, exp the 40mph limit out of Barnstaple) and got home at about 7pm. So 6hrs of riding and another 250 miles done. I did think of taking the roads to Dorset and try and work down the A38 towards the East of Cornwall but a) I ache a little b) The G7 Summit was going on down there and would prefer to keep out of it.

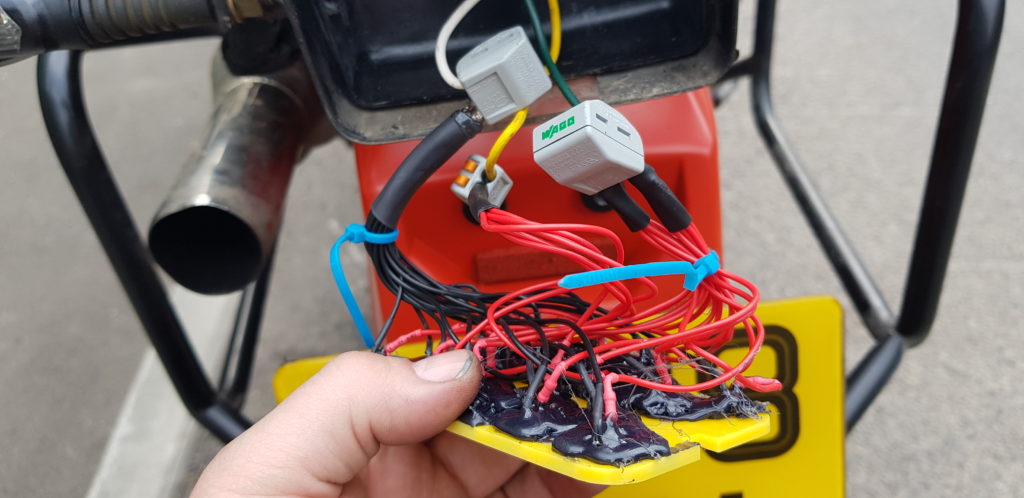

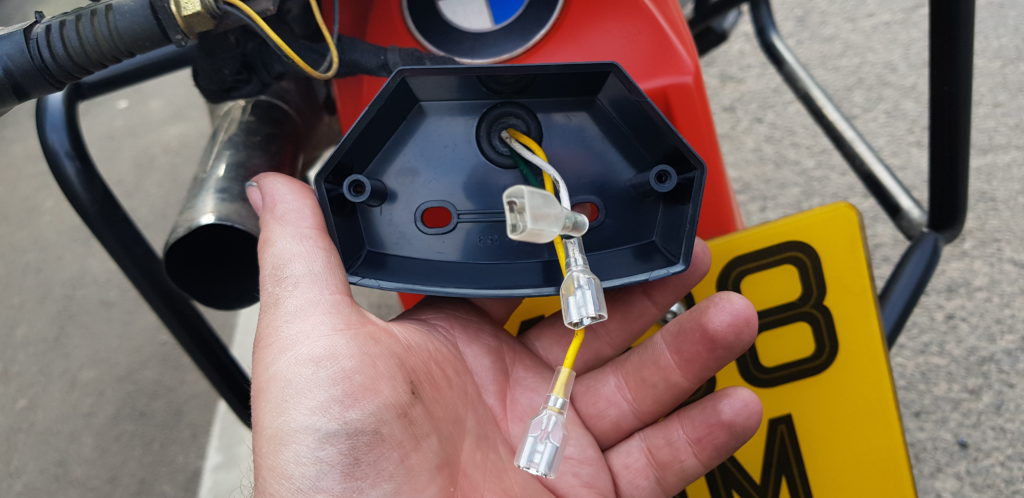

In other news I fitted a Honda CBX500 sat nav holder to the BMW during the week and the phone is fitted to it so I can see any Navigation tips it has for me. I also paired this with a set of Bluetooth headset things that were only £23 (SONY WI-C200 Wireless Bluetooth Headphones) which lasted the day and though not much good at motorway speeds I was able to listen to planet rock for most of the ride.

So in a month or so of riding, I have already done 1k of miles on the bike and 23hrs of saddle time.